Understanding Spiral Wound Membranes: Benefits, Applications, and More

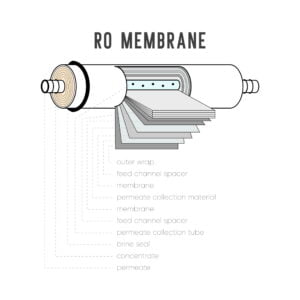

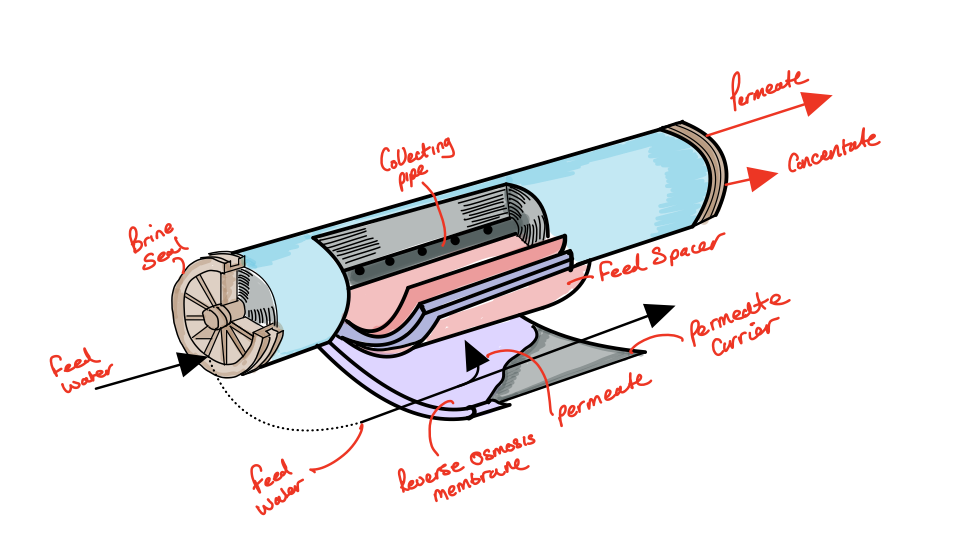

A spiral wound membrane is a type of thin film composite (TFC) membrane used in reverse osmosis (RO) water treatment systems. It consists of a thin, porous polymer membrane that is spirally wound around a permeate collection tube and sealed in a permeate delivery header.

The spiral wound design allows for a large surface area of the membrane to be exposed to the feed water, increasing the efficiency of the RO process. The thin film composite membrane is capable of removing a wide range of contaminants from the water, including dissolved salts, minerals, and organic matter.

One of the advantages of spiral wound membranes is their compact design, which allows for a relatively small footprint and a high concentration of membrane area per unit volume. This makes spiral wound membranes a popular choice for many large-scale water treatment applications, such as desalination and municipal water treatment.

Another advantage of spiral wound membranes is their modular design, which allows for easy maintenance and replacement of individual membranes. This helps to reduce downtime and minimize the overall cost of ownership for the RO system.

Overall, spiral wound membranes are a highly effective and efficient solution for water treatment, and they play a critical role in a wide range of applications.