How Activated Carbon Can Safely Remove Chlorine from RO Feed Water

It is common practice to use chlorine as a pretreatment because it helps to control biofouling, which can occur as a result of the buildup of biological material on membrane surfaces, thereby affecting the effectiveness of ROs.

A common problem with RO systems is biofouling, especially when using seawater or other high-fouling feedwaters, which makes them susceptible to biofouling. As a strong oxidizing agent, chlorine has the potential to kill bacteria, viruses, and other microorganisms that may otherwise attach to the membrane surface and form biofilms. This is a result of the chemical reaction. Chlorine can help to prevent biofouling by reducing the amount of organic matter and microorganisms in the feedwater. This will prolong the life of RO membranes and prevent biofouling in the RO system.

The use of chlorine within the feedwater can not only prevent biofouling from occurring, but is also effective at removing some other contaminants as well. These contaminants include ammonia and certain types of organic matter. There is, however, a need to use the right amount of chlorine and to monitor its concentration carefully. An excess of chlorine can damage the RO membrane and reduce its efficiency as well.

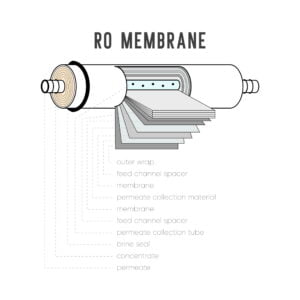

High concentrations of chlorine or prolonged exposure to chlorine can damage RO membranes. In particular, thin-film composite (TFC) membranes are susceptible to damage from chlorine, which is a strong oxidizing agent.

There are a number of ways that chlorine can damage the RO membrane when it reacts with it. Polymer chains in the membrane can be broken down, which reduces the membrane’s ability to reject contaminants and deteriorates its integrity. Additionally, chlorine can make the membrane more hydrophilic, increasing fouling potential and reducing permeability.

A number of disinfection byproducts (DBPs) can also be formed when chlorine reacts with organic matter in the feedwater, such as trihalomethanes (THMs) and haloacetic acids (HAAs), which can accumulate on the membrane surface and affect its performance. It is important to select the appropriate RO membrane type for the specific feedwater and operating conditions based on how much chlorine the membrane is resistant to.

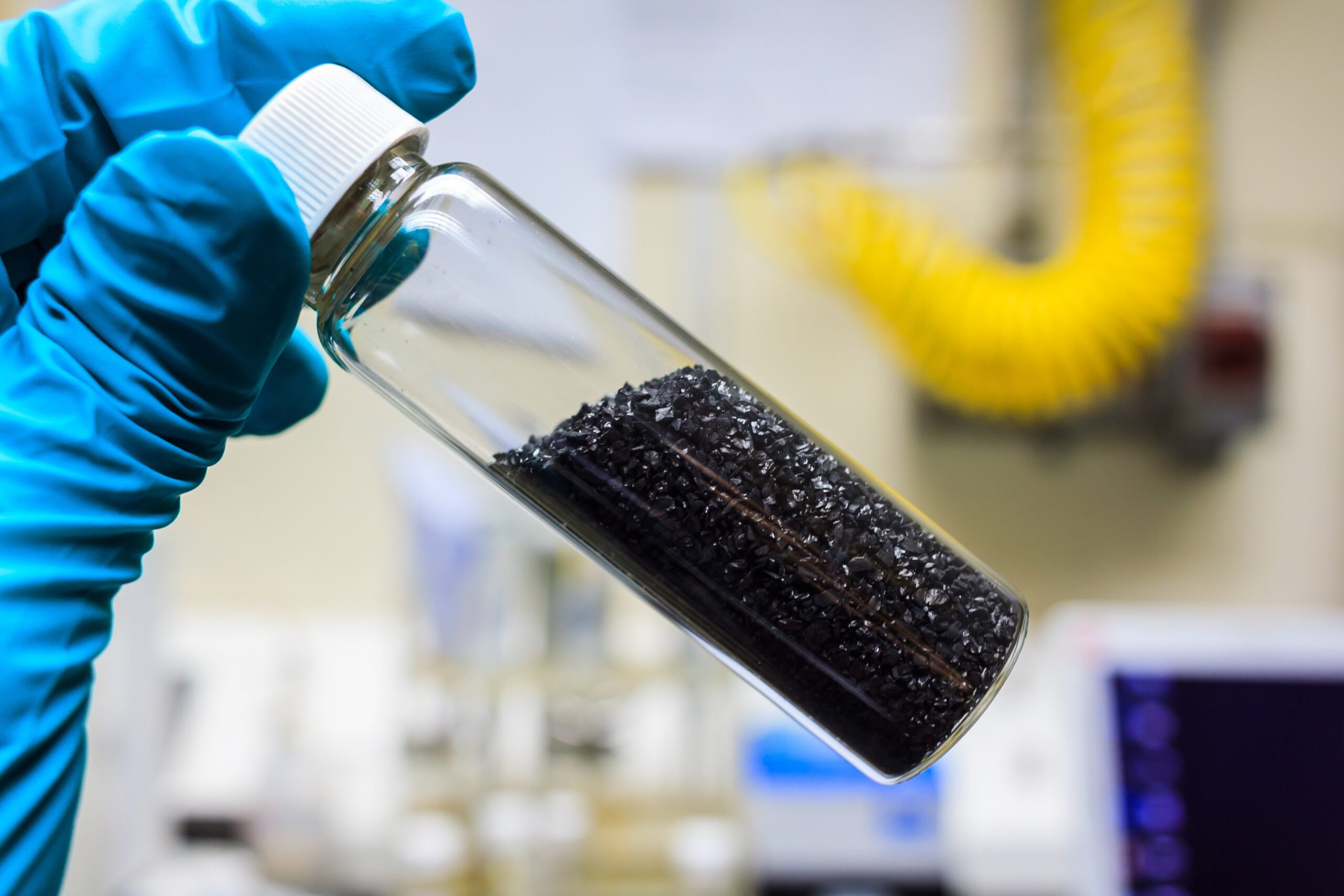

Feedwater is often treated with activated carbon before entering an RO system to remove chlorine. Activated carbon works by adsorbing chlorine onto its surface, where it is held and removed from the water.

The porosity of activated carbon, along with its large surface area, makes it an excellent adsorbent for chlorine and other contaminants. When water containing chlorine comes into contact with activated carbon, the chlorine molecules are attracted to the carbon’s surface and adhere to it. By doing this, chlorine is removed from the water and is prevented from damaging the RO membrane.

When it comes to removing chlorine from RO membranes, activated carbon is particularly effective at removing free chlorine. Free chlorine is the type of chlorine that is most likely to damage membranes.

Activated carbon must be replaced when it becomes saturated with chlorine to prevent breakthrough and subsequent chlorine damage to the RO membrane.