Maximize Efficiency: Regular CIP Regime for RO Membranes

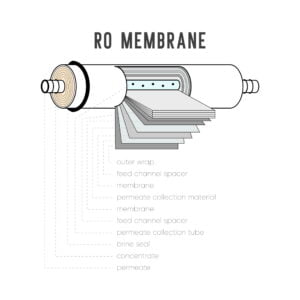

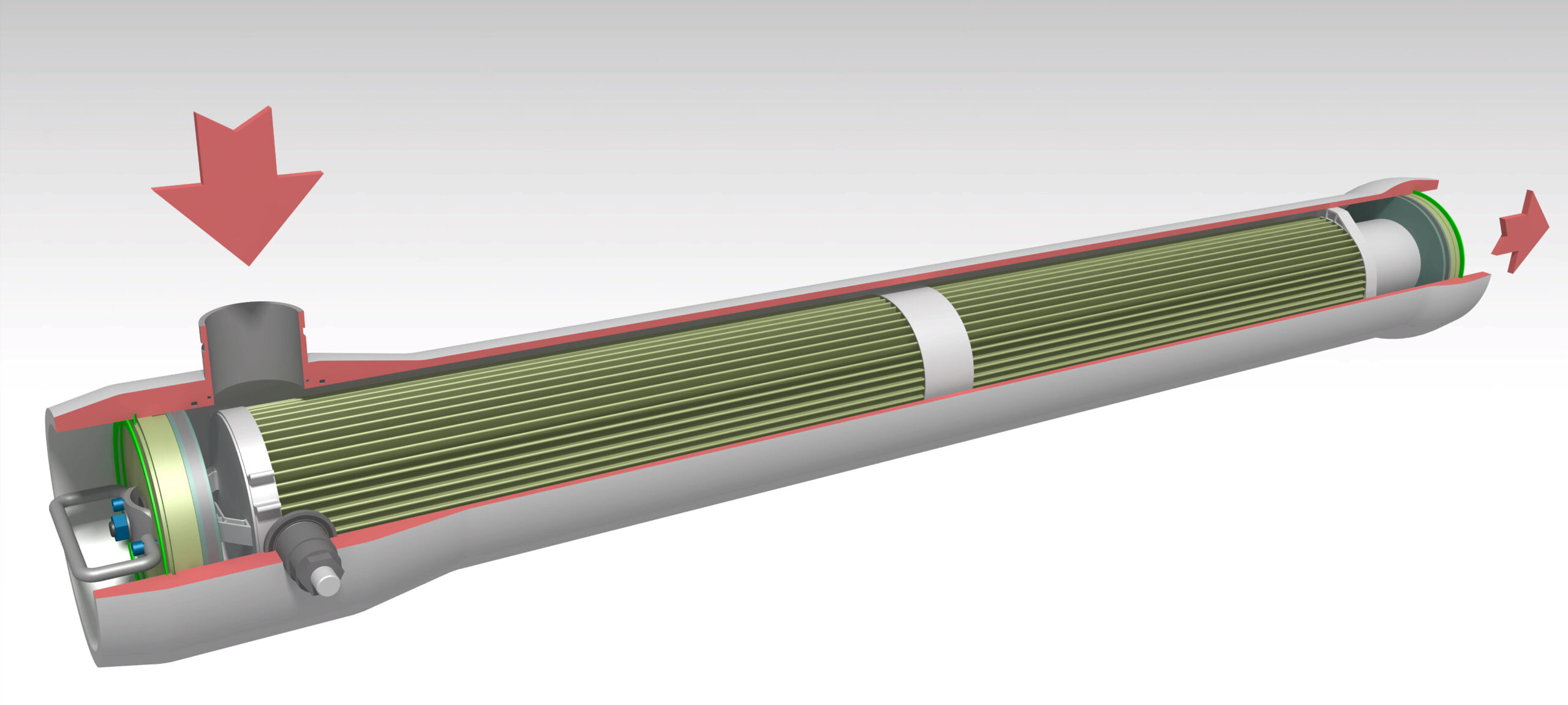

Reverse osmosis (RO) membranes are widely used in various industries such as food and beverage, pharmaceuticals, and electronics. These membranes are responsible for removing impurities and contaminants from water, making them an essential component of many manufacturing processes. However, over time, RO membranes can become fouled and damaged, leading to reduced efficiency and increased maintenance costs. To prevent this, it is essential to implement a regular cleaning regime, also known as Clean-In-Place (CIP), for RO membranes.

Understanding the Importance of CIP for RO Membranes

CIP is a critical maintenance process that involves cleaning various parts of a water filtration system, including membranes, without disassembling the system. Regular CIP helps to remove accumulated debris, bacteria, and other contaminants that can clog and damage RO membranes. Failure to conduct a regular CIP can lead to reduced efficiency, increased operating costs, and even system failure.

CIP for RO membranes should be performed at regular intervals based on the manufacturer’s recommendations or the operating conditions of the system. The frequency of CIP depends on the type of membrane, feed water quality, and the operating conditions of the system. Skipping or delaying CIP can cause irreversible damage to the RO membranes and reduce their lifespan.

Key Steps to Implement a Regular CIP Regime for Maximum Efficiency

To maximize the efficiency of an RO system, it is essential to implement a regular CIP regime. The following are the key steps involved in implementing a regular CIP regime:

- Conduct a thorough system analysis to determine the optimal CIP frequency and procedure.

- Prepare the CIP solution according to the manufacturer’s instructions.

- Flush the system with clean water to remove any loose debris.

- Circulate the CIP solution through the system for the recommended time.

- Rinse the system with clean water to remove the CIP solution and any remaining debris.

- Perform a post-CIP analysis to confirm that the system is clean and functioning correctly.

Implementing a regular CIP regime for RO membranes can help to extend their lifespan, improve efficiency, and reduce operating costs. It is essential to follow the manufacturer’s recommendations and work with an experienced water treatment professional to ensure that the CIP process is performed correctly.

In conclusion, RO membranes are a vital component of many manufacturing processes. To ensure their optimal performance, it is essential to implement a regular CIP regime. This maintenance process helps to remove accumulated debris, bacteria, and other contaminants that can clog and damage RO membranes. By following the appropriate CIP procedures and working with experienced water treatment professionals, companies can maximize the efficiency of their RO systems and reduce operating costs.