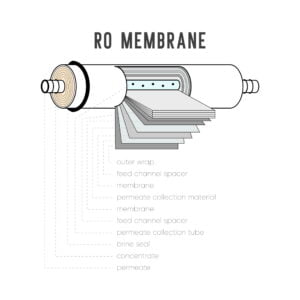

RO Membrane Cleaning

Reverse Osmosis (RO) membrane cleaning is crucial for maintaining the efficiency and longevity of RO systems, whether used for water purification, desalination, or other applications. Cleaning helps remove fouling, scaling, and organic matter that can accumulate on the membrane surface. We use different methods for our off-site cleaning, below are some of the examples of methods and techniques available at our off-site cleaning depot and methods for you fixed plant on site.

- Chemical Cleaning:

- Acid Cleaning: Inorganic scale deposits like calcium carbonate and calcium sulfate can be dissolved using acidic solutions such as citric acid, hydrochloric acid, or sulfuric acid. Acid cleaning is effective against mineral scale fouling.

- Alkaline Cleaning: Organic fouling and some forms of biological fouling can be treated with alkaline cleaning agents like sodium hydroxide (caustic soda) or sodium carbonate (soda ash).

- Surfactant Cleaning: Organic fouling, such as oils and greases, can be removed using surfactant-based cleaners. Surfactants help to emulsify and disperse organic substances.

- Mechanical Cleaning:

- Backwashing: Regularly reversing the flow through the RO membrane to dislodge particles and debris on the membrane surface. This is typically done with clean water or low-pressure air.

- Air Scouring: Introducing air or inert gases into the feedwater to create bubbles that agitate the membrane surface and dislodge fouling.

- Brushing or Scrubbing: Some systems employ soft brushes or sponges to physically scrub the membrane surface to remove fouling.

- Biological Cleaning:

- Biofilm Removal: Biofilms consisting of bacteria and other microorganisms can develop on RO membranes. Specialized cleaning solutions containing biocides or enzymes can be used to break down and remove biofilms.

- Advanced Techniques:

- Ultrasonication: The use of high-frequency ultrasound waves to dislodge and remove fouling from the membrane surface.

- Pulse Cleaning: Intermittently varying the pressure or flow rates during the cleaning process to create a pulsing effect that helps dislodge fouling.

- Ozone Cleaning: Ozone gas can be used to break down organic fouling and kill microorganisms on the membrane surface.

- Soaking and Flushing:

- Soaking the membranes in a cleaning solution for a specified duration to allow the chemicals to react with and loosen fouling. Followed by thorough flushing to remove the loosened debris.

- Preventive Maintenance:

- Regularly scheduled maintenance and cleaning can help prevent fouling from becoming severe. This includes routine inspections and cleanings even when performance hasn’t significantly degraded.

- Chemical Enhancers:

- Some cleaning methods may benefit from the addition of chemical enhancers or complexing agents that improve the efficacy of the cleaning solutions.

It’s important to note that the choice of cleaning method depends on the nature of fouling (scale, organic, biological), the type of membrane material, and the specific RO system’s design and operating conditions. Proper monitoring and analysis of the fouling issue are essential to determine the most appropriate cleaning method for each situation. Additionally, following manufacturer recommendations and guidelines is critical to avoid damage to the membranes during cleaning procedures.

Speak to one of our team or post a question in our forum for advice.